Peptides are naturally occurring substances in all living species. Yet, synthetic manufacturing is required for multiple purposes. The usage of manufactured peptides is not limited to ensuring adequate protein percentage. In fact, it is also used for diverse research in the food and agricultural sectors.

However, have you ever wondered about the intricate manufacturing process? Knowing about the production process before you buy peptides is always advisable. Sounds intriguing? Read this article to arm yourself with detailed knowledge of the steps and their alternatives. Scroll down for more information.

Table of Contents

Steps And Types Of Peptide Synthesis

There are three two major steps involved in the whole procedure – Production and Purification. There are various methods registered companies like Lotilabs use to complete these two steps. Without any further delay, let us delve into more details.

1. Production

This process includes identifying and acquiring the target peptide. You can either extract it from the parent protein or utilize other methodologies. The three major processes are listed below.

Enzymatic Fermentation and Microbial Fermentation

Extracting peptides from food through fermentation and treating them with hydrolytic enzymes is one of the initial ways of production. The best source of bioactive proteins is dairy products. Moreover, enzymes like thermolysin are responsible for acquiring hypotensive peptides from food items such as corn. Hydrolysis is usually performed with operating batches in a discontinuous process within a reactor.

Chemical Synthesis

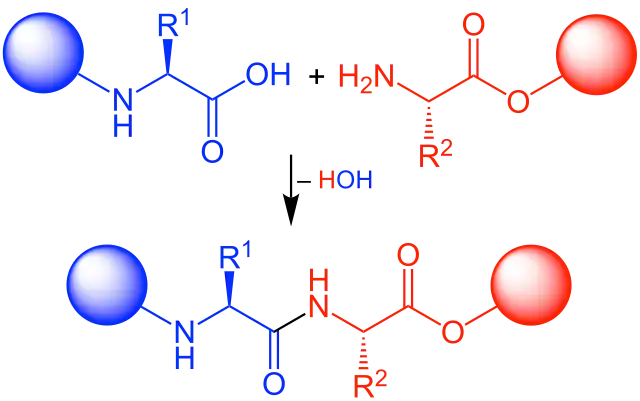

This is certainly a more efficient process, especially when dealing with large production quantities. They are mainly produced in the solid or liquid phase. Here, the protein components of the required peptide are incorporated into the mixture. It is produced by reacting with the growing chain. In the solid phase, commonly abbreviated as SPPS, a single N-protected amino acid is involved in the reaction. While in the liquid phase or LPPS stirred batch, flow or continuous-flow reactors are utilized to carry out the process.

Recombinant Approach

This is specifically used to produce peptides with natural amino acids. The recombinant approach achieves more sustainability in the production process than the others. The most common host for this genetic engineering process is Escherichia coli. The steps involved in this production process are as follows: choosing the right expression system, constructing expression vectors, and developing the bioprocess.

2. Purification

This is the second step of the overall process. After the production, the end product is received with various impurities. Hence, purification is required to eliminate unnecessary residues. The two major types of purification process are

Reversed-Phase Liquid Chromatography

This technique separates the analytes from the protein or peptide mixtures depending on their hydrophobic properties. You may wonder why it is more popular than other chromatographic modes. This is mainly because of the solvents that can be integrated with mass spectrometry.

Ion-Exchange Chromatography

This separation occurs through the electrostatic interactions between opposite charges of analytes and the stationary phase. This method can also be used to pre-purify the required peptide.

Ending Notes

We hope you have understood the industrial process of manufacturing. The choice of process mainly depends on the type of peptide used and the objective of manufacturing. Hence, as a buyer, you must be well-versed to communicate your preferences.