Hot working is a highly effective metalworking process that shapes and forms materials at elevated temperatures. Subjecting metals to heat during the manufacturing process can improve their mechanical properties, allowing for enhanced ductility, reduced strength, and increased formability. This article explores the concept of hot working and its various techniques, benefits, and applications in material science and engineering.

I. Understanding Hot Working

Hot working is a metalworking process that involves deforming and shaping metals and alloys at temperatures above their recrystallization temperature. Unlike cold working, which is performed at room temperature, hot working takes advantage of the increased flexibility and reduced strength of materials at elevated temperatures. This process can be carried out through various techniques, including rolling, forging, extrusion, and heat treatment.

II. Techniques of Hot Working

Rolling

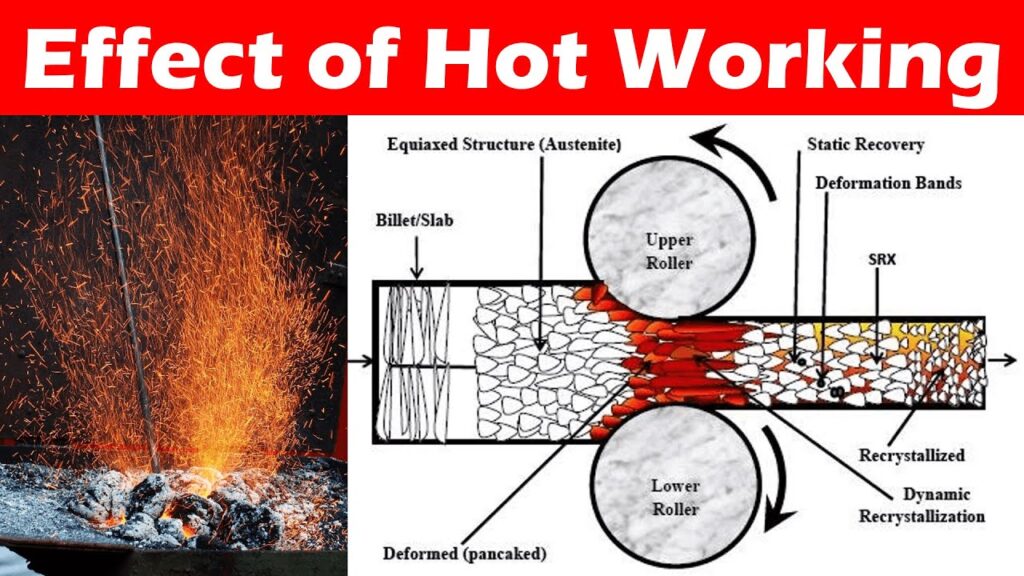

Rolling is a common hot workings technique that involves passing the metal through rotating rolls to reduce its thickness and shape it into desired forms. The hot rolling process enhances the material’s grain structure, making it more uniform and reducing defects such as voids and cracks. This technique is commonly used in producing sheets, plates, and structural components.

Forging

Forging is another widely used hot working method where metal is shaped by applying compressive forces using a hammer or press. The metal is heated to a suitable temperature to increase its plasticity, allowing for deformation. The forged components possess improved mechanical properties, including higher strength, toughness, and resistance to fatigue. Forging is commonly employed in manufacturing automotive parts, aircraft components, and tools.

Extrusion

Extrusion involves forcing heated metal through a die to create long continuous profiles with a consistent cross-section. This process extensively produces pipes, rods, and complex cross-sectional shapes. The hot extrusion method produces products with enhanced mechanical properties, precise dimensions, and improved surface finish.

Heat Treatment

Heat treatment is a hot workings technique that involves controlled heating and cooling of metals to alter their microstructure and enhance their properties. Processes such as annealing, normalizing, and tempering are commonly employed to improve the material’s toughness, hardness, and machinability. Heat treatment is extensively used in steel manufacturing. Which helps optimize the final product’s mechanical properties.

III. Benefits of Hot Working

Hot working offers several advantages over cold working techniques. Some notable benefits include:

Improved Ductility: Hot workings allows metals to be deformed with greater ease and reduced resistance. This increased flexibility enhances the material’s ability to be shaped into complex forms without cracking or fracturing.

Reduced Strength: Elevated temperatures lower metals’ yield and tensile strength, making them more malleable. This enables the creation of intricate designs and facilitates the forming process.

Enhanced Formability: Hot working improves the formability of materials. Enabling them to be molded into intricate shapes and structures that would be difficult or impossible to achieve through cold working alone.

Grain Refinement: The heat and mechanical stress applied during hot workings lead to forming smaller and more uniform grain structures in metals. This improves mechanical properties, such as increased strength and reduced brittleness.

IV. Applications.

Hot working finds extensive applications across various industries, including:

Automotive Industry: Hot workings techniques are used to produce engine components, transmission parts, and suspension systems, where enhanced mechanical properties and complex shapes are required.

Aerospace Industry: The aerospace sector utilizes hot workings methods to manufacture critical components, such as turbine blades, aircraft frames, and landing gear, which demand high strength, fatigue resistance, and dimensional accuracy.

Construction Sector: Hot working is employed in the construction industry to fabricate structural steel elements, beams, and columns, ensuring they possess the required strength, durability, and formability.

Oil and Gas Sector: Pipes, valves, and other equipment used in the oil and gas industry often undergo hot working processes to meet the stringent requirements of this demanding sector.

Conclusion

Hot working is a vital metalworking process that enhances material properties by applying heat. Subjecting metals to elevated temperatures can improve their ductility, formability, and grain structure, leading to enhanced mechanical properties. The various hot workings techniques, including rolling, forging, extrusion, and heat treatment, offer various applications across the automotive, aerospace, construction, and oil and gas industries. With its numerous benefits, hot working continues to play a pivotal role in manufacturing high-quality metal components and structures.